RTO Carports Your Guide to Smart Vehicle Protection

RTO carports offer a practical and stylish solution for protecting your vehicles from the elements. They provide a balance between the full enclosure of a garage and the open-air simplicity of a simple carport, offering various customizable options in terms of size, materials (like metal, wood, or polycarbonate), and design. This guide will explore everything you need to know about RTO carports, from understanding their benefits and construction to navigating regulations and maintenance.

We’ll delve into the different types of RTO carports available, comparing their features and costs to other vehicle protection methods. We’ll also cover the crucial aspects of obtaining permits, choosing appropriate materials, and ensuring your carport stands the test of time through proper maintenance. By the end, you’ll be well-equipped to make an informed decision about whether an RTO carport is the right choice for your needs.

Defining RTO Carports

Source: okezone.com

RTO carports, in the context of automotive repair and storage, refer to structures designed to provide covered parking and often additional workspace for vehicles undergoing repair or maintenance. They’re commonly used by individuals, small repair shops, or even larger dealerships as a cost-effective alternative to fully enclosed garages. The “RTO” likely refers to “repair, testing, or other” operations, though the precise acronym isn’t standardized across the industry.

RTO carports offer a practical solution for protecting vehicles from the elements while providing convenient access for repairs. Unlike enclosed garages, they allow for better ventilation and easier access to the vehicle from multiple sides. This accessibility can be particularly beneficial for mechanics and DIY enthusiasts working on vehicles.

Types of RTO Carports

The variety in RTO carports is extensive, catering to diverse needs and budgets. Size is a primary differentiator; smaller carports might only accommodate a single vehicle, while larger structures can house multiple cars or even include additional workspace areas. Materials commonly used include metal (steel or aluminum), wood, and combinations thereof. Metal carports are often favored for their durability and relatively low cost, while wood carports can offer a more aesthetically pleasing, traditional look. Design options range from simple, open-sided structures to more complex designs incorporating walls, storage compartments, and even integrated lighting.

Features and Functionalities of RTO Carports

Typical features of RTO carports include a sloped roof to facilitate water runoff, sturdy support posts, and a robust framework to withstand various weather conditions. Some carports may include additional features such as reinforced flooring to support heavier vehicles or equipment, integrated lighting for improved visibility during evening work, electrical outlets for powering tools, and built-in storage for parts and tools. The functionalities extend beyond simple shelter; they create a dedicated, weather-protected space ideal for vehicle maintenance, repairs, and storage, improving both efficiency and safety for the user.

Benefits of RTO Carports

Source: com.au

RTO carports offer a compelling blend of protection, affordability, and environmental consciousness compared to other vehicle storage solutions. They provide a significant upgrade over leaving your vehicle exposed to the elements while remaining a more budget-friendly option than a fully enclosed garage. Let’s explore the advantages in detail.

Vehicle Protection

RTO carports offer substantial protection against the damaging effects of sun, rain, snow, and hail. The roof shields your vehicle from UV rays, preventing fading and deterioration of paint and interior materials. The structure also provides a degree of protection against falling debris and bird droppings. While not completely enclosed, this partial protection significantly extends the lifespan and aesthetic appeal of your car compared to uncovered parking.

Economic Advantages

The initial cost of an RTO carport is generally much lower than constructing a garage. This makes them an attractive option for budget-conscious car owners. Furthermore, the reduced exposure to the elements can translate into lower long-term maintenance costs. By protecting your vehicle from harsh weather, you minimize the need for frequent repairs and repainting, ultimately saving you money over the vehicle’s lifetime. For example, avoiding hail damage alone can save thousands of dollars in repair bills.

Environmental Considerations

While not directly reducing emissions, RTO carports contribute indirectly to environmental sustainability. By protecting your vehicle from the elements, you reduce the need for frequent washes and detailing, thereby conserving water and reducing the use of cleaning chemicals. The use of recycled materials in some RTO carport constructions further enhances their environmental friendliness. Choosing a carport made from sustainable materials, such as recycled metal or treated lumber from responsibly managed forests, can minimize the environmental impact of your purchase.

RTO Carports vs. Other Vehicle Protection Methods

| Feature | RTO Carport | Garage | Car Cover |

|---|---|---|---|

| Cost | Low | High | Low to Moderate |

| Protection from Elements | Partial (sun, rain, snow, some debris) | Complete | Partial (sun, rain, some debris) |

| Security | Low | High | Low |

| Maintenance | Low | Moderate | Low |

Materials and Construction of RTO Carports

Source: nairaland.com

RTO carports, designed for temporary or readily transferable use, require materials and construction methods that prioritize ease of assembly, disassembly, and relocation. The choice of materials significantly impacts the carport’s durability, lifespan, and overall cost.

Choosing the right materials and construction techniques is crucial for a sturdy and long-lasting RTO carport. Several factors influence this decision, including budget, desired lifespan, and the frequency of relocation.

Common Materials Used in RTO Carport Construction

The most common materials for RTO carports are designed for lightweight portability and reasonable durability. Steel, aluminum, and high-density polyethylene (HDPE) are frequently used, each offering unique advantages and disadvantages. Steel offers strength but can be heavy and prone to rust; aluminum is lightweight and rust-resistant but can be more expensive; HDPE is lightweight, durable, and relatively inexpensive but may not be as strong as steel or aluminum.

Durability and Lifespan Comparison of RTO Carport Materials

Steel carports, when properly treated against rust (e.g., with galvanization or powder coating), can last for many years, potentially exceeding 20 years with minimal maintenance. Aluminum carports, being naturally rust-resistant, often boast similar lifespans. HDPE carports, while less susceptible to rust and rot, may be more prone to damage from UV exposure and impact, potentially leading to a shorter lifespan of 10-15 years, depending on the quality of the plastic and environmental conditions.

Steps Involved in the Construction of an RTO Carport

The construction process for an RTO carport varies depending on the materials used and the carport’s design. However, several common steps generally apply. First, a level and stable foundation is prepared, often using concrete blocks or a compacted gravel base. Then, the supporting frame is assembled, typically consisting of posts, beams, and rafters. Next, the roofing material is attached to the frame. Finally, any necessary anchoring or securing mechanisms are implemented to ensure stability and prevent movement in windy conditions. For steel or aluminum carports, this might involve bolting components together; HDPE carports may utilize interlocking systems.

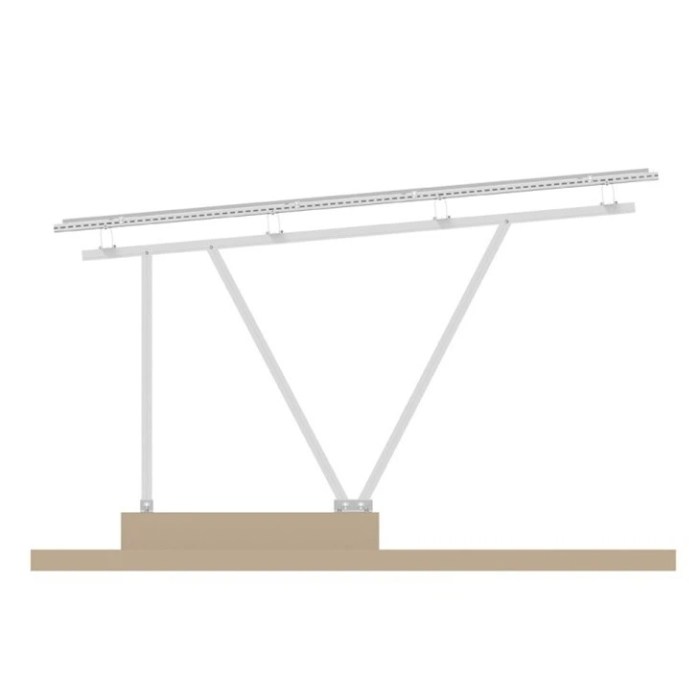

Structural Components of a Typical RTO Carport

A typical RTO carport’s structure can be represented as follows: Imagine a rectangular frame, with four vertical posts at each corner providing the foundation. Horizontal beams connect these posts at the top and bottom, forming a rigid structure. Rafters span between the beams, creating the roof structure. The roofing material (e.g., corrugated metal, polycarbonate sheets, or HDPE panels) is then fixed to the rafters. The entire structure might include anchoring points or weights at the base for added stability.

Regulations and Permits for RTO Carports

Source: com.au

Building an RTO (Ready-to-Occupy) carport involves navigating local regulations and obtaining the necessary permits. Understanding these requirements is crucial to avoid delays and potential legal issues. This section evaluates the key aspects of the permitting process and potential challenges.

Permitting Requirements for RTO Carports

Securing the necessary permits for your RTO carport will vary depending on your location. Generally, you’ll need to contact your local building department or planning office to determine the specific requirements. This usually involves submitting detailed plans of your carport’s design, including dimensions, materials, and foundation type. The approval process often includes inspections at various stages of construction to ensure compliance with building codes. Some jurisdictions may have streamlined processes for smaller structures like carports, while others might require more extensive reviews. Expect to pay permit fees, which vary based on the project’s size and complexity.

Zoning Regulations and Restrictions

Zoning regulations dictate how land can be used within a specific area. These regulations often affect the placement and design of structures like carports. For example, setbacks (minimum distances from property lines) are common restrictions. Height limitations may also apply, preventing carports from exceeding a certain height. Additionally, zoning regulations might dictate the allowed materials and the overall aesthetic compatibility with surrounding structures. Before starting construction, review your local zoning ordinances to ensure your carport design complies with all applicable regulations. Failing to comply could lead to costly modifications or even demolition orders. For instance, a carport built too close to a property line might be deemed a violation and require relocation.

Relevant Building Codes and Standards

RTO carport construction must adhere to local building codes and standards, which are designed to ensure safety and structural integrity. These codes cover aspects like wind load resistance, snow load capacity, and the use of approved materials. For example, codes often specify minimum requirements for foundation strength and anchoring to withstand extreme weather conditions. Specific codes regarding electrical installations within or near the carport will also need to be addressed if you plan to include lighting or power outlets. Ignoring building codes can lead to structural failures, safety hazards, and potential legal consequences. Consulting with a qualified structural engineer or architect is recommended to ensure compliance.

Potential Challenges in Obtaining Permits

Obtaining permits for an RTO carport can present several challenges. These may include navigating complex bureaucratic processes, delays due to incomplete applications or required revisions, and difficulties in interpreting ambiguous regulations. Another challenge is the possibility of encountering unexpected zoning restrictions or code requirements that necessitate design changes. In some cases, obtaining necessary approvals from multiple agencies (e.g., building department, environmental protection agency) can further complicate the process and add to the timeline. Proactive planning, thorough research, and consultation with relevant professionals can help mitigate these challenges. For example, having detailed plans prepared by a professional architect can significantly streamline the permit application process.

Maintenance and Care of RTO Carports

Source: wordpress.com

Proper maintenance is key to extending the life and ensuring the structural integrity of your Ready-to-Occupy (RTO) carport. Regular inspections and timely repairs will prevent costly damage and keep your carport looking its best. Neglecting maintenance can lead to premature deterioration and compromise the safety of your vehicle and property.

Step-by-Step Maintenance Guide

A regular maintenance schedule is crucial for your RTO carport. This involves visual inspections and some simple upkeep tasks. Start by visually inspecting the entire structure at least twice a year, more frequently in harsh weather conditions. Pay close attention to areas prone to wear and tear.

- Roof Inspection: Check for any signs of damage, such as cracks, holes, or loose panels. Look for missing or damaged sealant around joints and ensure the roof is securely fastened. Address any issues immediately to prevent water damage.

- Frame Inspection: Examine the supporting frame for rust, warping, or loose connections. Tighten any loose bolts or screws. If you notice significant rust, consider repainting the metal components with a rust-resistant paint.

- Gutter and Drainage Check: Clean gutters and downspouts regularly to prevent water accumulation. Ensure water drains away from the carport’s foundation to avoid water damage to the base and surrounding area.

- Cleaning: Regularly clean the carport using a garden hose and mild detergent. Avoid using high-pressure washers, which can damage the structure. For stubborn stains, use a suitable cleaning solution appropriate for the carport’s materials.

Common Issues and Solutions

Several common problems can affect RTO carports. Understanding these and their solutions will help you proactively address issues and prevent larger, more expensive repairs.

| Problem | Solution |

|---|---|

| Rust on metal components | Clean the affected area, apply a rust converter, and then repaint with a rust-resistant paint. |

| Loose or damaged panels | Tighten loose screws or replace damaged panels. Use appropriate sealant to ensure a watertight seal. |

| Water damage to the roof | Repair any cracks or holes in the roof. Ensure proper drainage to prevent water accumulation. |

| Sagging roof or frame | This could indicate structural issues. Contact a qualified professional for inspection and repair. |

Extending the Lifespan of Your RTO Carport

Proper maintenance significantly extends the lifespan of your RTO carport. By regularly inspecting and addressing minor issues promptly, you can prevent them from escalating into major problems requiring extensive and costly repairs. This proactive approach protects your investment and ensures the long-term functionality and structural integrity of your carport.

Recommended Maintenance Tasks and Frequency

- Visual inspection: Twice a year, more often in extreme weather.

- Gutter and downspout cleaning: Twice a year, or as needed after heavy rainfall.

- Roof cleaning: As needed, to remove debris and prevent build-up.

- Frame inspection and tightening of bolts: Annually.

- Repainting (if needed): Every 3-5 years, depending on the material and environmental conditions.

Cost Considerations for RTO Carports

Source: com.au

Planning for an RTO carport involves understanding the associated costs, which can vary significantly depending on several factors. This section provides a breakdown of typical expenses and helps you estimate the total cost of your project. Accurate budgeting is crucial to avoid unexpected financial burdens during the construction phase.

Typical Cost Breakdown

The cost of an RTO carport is typically broken down into materials, labor, and permits. Materials comprise the primary structural components like posts, beams, roofing, and fasteners. Labor costs cover the professional installation, including site preparation and assembly. Permit fees vary based on location and regulations. A rough estimate might place materials at 40-50% of the total cost, labor at 30-40%, and permits at 10-20%. However, these percentages are approximate and can fluctuate widely.

Factors Influencing Overall Cost

Several key factors significantly impact the final cost of an RTO carport. The size of the carport is a major determinant, with larger structures naturally costing more due to increased material and labor requirements. The choice of materials also plays a crucial role; higher-quality, more durable materials like steel or treated lumber will be more expensive than less durable alternatives. The location of the installation can influence costs as well; difficult terrain or remote locations may necessitate additional labor and transportation expenses. Finally, the complexity of the design, including features like additional supports or custom roofing, will increase the overall cost.

Cost Comparison of Different RTO Carport Options, RTO carports

The market offers various RTO carport options, each with its price range. A basic, single-car carport made from standard materials and requiring minimal customization will generally be the most affordable option. Larger, multi-car carports, or those incorporating premium materials like aluminum or high-grade steel, will be significantly more expensive. Similarly, carports with more complex designs, such as those with sloped roofs or integrated storage, will command a higher price. Prefabricated kits often represent a cost-effective solution, offering a balance between affordability and convenience, while custom-built carports provide maximum flexibility but at a higher cost.

Estimating Total Cost Using Example Figures

Let’s illustrate cost estimation with an example. Consider a 10ft x 20ft single-car carport constructed using treated lumber and a standard metal roof. Assuming material costs of $2,000, labor costs of $1,500, and permit fees of $500, the total estimated cost would be $4,000. However, this is a simplified estimate. A larger, more elaborate structure using higher-quality materials and requiring more complex installation could easily cost $8,000 or more. Conversely, a smaller, simpler carport might be built for under $3,000. Always obtain multiple quotes from reputable contractors to ensure accurate cost assessment tailored to your specific needs and location.

Final Conclusion

Source: com.au

Ultimately, choosing the right RTO carport depends on your specific needs and budget. By carefully considering the factors discussed – materials, costs, regulations, and maintenance – you can select a carport that offers optimal protection for your vehicle while enhancing your property’s aesthetic appeal. Remember to factor in local regulations and seek professional advice when necessary to ensure a smooth and successful installation process. With a little planning, your RTO carport will provide years of reliable service, safeguarding your investment and adding value to your property.