Metal Barricades for Sale Your Guide

Metal barricades for sale are more than just barriers; they’re versatile tools crucial for safety, security, and crowd control across various sectors. From construction sites humming with activity to bustling concert venues, these sturdy structures play a vital role in organizing space and ensuring safety. This guide dives deep into the world of metal barricades, exploring their different types, applications, pricing, and maintenance, helping you make informed decisions for your specific needs.

We’ll cover everything from the differences between temporary and permanent barricades to the various materials used in their construction and the factors affecting their price. We’ll also discuss safety regulations, maintenance tips, and where to find reputable suppliers. By the end, you’ll be equipped to choose the right metal barricade for your project, ensuring both safety and efficiency.

Types of Metal Barricades

Source: alicdn.com

Metal barricades come in various forms, each designed for specific applications and offering different levels of durability and portability. Understanding the distinctions between these types is crucial for choosing the right barricade for your needs, whether it’s for a construction site, a public event, or a permanent security measure.

Metal Barricade Types

Several key types of metal barricades exist, each with its unique characteristics. These differences stem from the intended use, required strength, and level of portability. Let’s explore some of the most common varieties.

Temporary Metal Barricades: These are lightweight and easily movable, ideal for short-term use at events, construction sites, or traffic control. They typically consist of a steel frame and often feature a powder-coated finish for weather resistance. Weight can range from 10 to 30 pounds, with heights averaging 3 to 4 feet. Materials commonly include mild steel or galvanized steel. They are frequently foldable or stackable for easy storage and transport.

Permanent Metal Barricades: These are heavier and more robust than temporary barricades, designed for long-term use and increased security. They are often anchored to the ground and made from thicker, more durable steel. Weights can exceed 100 pounds, and heights can reach 5 feet or more. They are frequently used for perimeter security, access control in industrial settings, or permanent traffic barriers. Materials include high-strength steel, sometimes with added features like reinforced joints or anti-climb designs.

Retractable Metal Barricades: These offer a flexible solution, allowing for quick deployment and retraction as needed. They are typically mounted to a wall or floor and consist of a series of interconnected sections that can be extended or retracted using a mechanism. Weight varies significantly depending on size and material, ranging from relatively light for smaller units to quite heavy for larger systems. Heights are adaptable, ranging from 3 to 6 feet. Materials are often chosen for durability and ease of movement, such as lightweight yet strong aluminum alloys or reinforced steel.

Portable Metal Barricades: This category encompasses barricades designed for easy transport and setup. Many temporary barricades fall under this umbrella, but portable barricades can also include heavier-duty models that are still manageable by a few people. They are often equipped with features like wheels or handles for easier movement. Weight and height vary depending on the specific design, but generally aim for a balance between portability and sturdiness. Materials are selected for a combination of strength and manageable weight, such as lightweight steel alloys or even aluminum in some cases.

Comparison of Metal Barricade Types

The table below provides a comparative overview of four common metal barricade types.

| Barricade Type | Strengths | Weaknesses | Typical Applications |

|---|---|---|---|

| Temporary | Lightweight, portable, inexpensive | Less durable, easily damaged, may not offer high security | Construction sites, events, short-term traffic control |

| Permanent | Durable, secure, weather-resistant | Heavy, difficult to move, expensive | Perimeter security, industrial settings, permanent traffic barriers |

| Retractable | Space-saving, flexible, convenient | Can be expensive, requires installation, potential for malfunction | Access control, crowd management, security checkpoints |

| Portable (Heavy-Duty) | Durable, portable (relatively), good security | Heavier than temporary barricades, less portable than temporary types | Construction sites requiring more robust security, outdoor events with higher security needs |

Metal Barricade Manufacturing Processes

The manufacturing process for metal barricades varies depending on the type and desired specifications. However, several common steps are involved. These generally begin with cutting and shaping the metal components (often using laser cutting or stamping for high precision). Welding is then used to join the pieces, creating the barricade’s frame. For enhanced durability and aesthetics, a powder coating process is often employed, providing a protective layer and a consistent finish. Finally, any additional features, such as handles, wheels, or anchoring points, are added. More complex barricades, like retractable ones, involve additional steps such as incorporating the retraction mechanism and testing its functionality. The specific materials and processes are tailored to meet the requirements of each barricade type, ensuring appropriate strength, durability, and cost-effectiveness.

Pricing and Market Analysis

Source: imimg.com

Understanding the pricing of metal barricades is crucial for both buyers and sellers. Prices vary significantly depending on several factors, making it essential to conduct thorough market research before making a purchase or setting prices. This section will explore typical price ranges, compare pricing strategies of different sellers, and identify key cost drivers.

Metal barricade pricing is complex, and influenced by a variety of interconnected factors. The type of barricade (e.g., standard, retractable, heavy-duty), the quantity ordered, and any additional features (e.g., reflective tape, custom branding) all play a significant role. For example, a simple, standard metal barricade might cost between $50 and $150 per unit, while a heavy-duty, retractable model with enhanced visibility features could easily exceed $300 per unit. Bulk purchases generally lead to discounts, potentially lowering the per-unit cost by 10-20% or more depending on the seller and order size. Budget-friendly options often compromise on durability and features, while high-end barricades prioritize strength, longevity, and safety enhancements.

Price Ranges and Examples

The following table illustrates typical price ranges for different types and quantities of metal barricades. These are estimates and actual prices may vary based on the supplier and prevailing market conditions. Note that these prices are USD and are approximate.

| Barricade Type | Quantity | Price Range per Unit ($) | Example Features |

|---|---|---|---|

| Standard | 1-10 | 75-125 | Steel construction, basic powder coating |

| Standard | 11-50 | 65-110 | Steel construction, basic powder coating |

| Heavy-Duty | 1-10 | 150-300 | Reinforced steel, reflective tape, heavier gauge metal |

| Retractable | 1-10 | 200-400 | Steel construction, retractable design, easy storage |

Pricing Strategies of Different Sellers

Analyzing the pricing strategies of different metal barricade sellers reveals diverse approaches to market competition. Some prioritize competitive pricing, others focus on premium quality and service, and still others leverage bulk discounts to attract large orders.

- Seller A: This seller focuses on competitive pricing, offering standard barricades at the lower end of the price range. They often run promotions and offer discounts for bulk orders. Their profit margin is likely lower, relying on high-volume sales.

- Seller B: This seller emphasizes high-quality, heavy-duty barricades and offers a range of customization options. Their prices are at the higher end of the spectrum, reflecting the superior materials and craftsmanship. Their strategy focuses on a niche market willing to pay a premium for durability and longevity.

- Seller C: This seller offers a balanced approach, providing a range of barricade types at various price points. They compete on both price and quality, offering discounts for bulk orders while maintaining a reasonable profit margin on individual sales. They may offer financing options to attract larger customers.

Factors Influencing Cost, Metal barricades for sale

Several factors contribute to the overall cost of metal barricades. Understanding these factors allows for a more informed purchasing decision.

- Raw Materials: The cost of steel, the primary material in metal barricades, fluctuates based on global market conditions and supply chain dynamics. Increased steel prices directly impact the manufacturing cost of barricades.

- Manufacturing: Labor costs, factory overhead, and the complexity of the manufacturing process influence the final price. More intricate designs and specialized features increase manufacturing costs.

- Shipping and Transportation: The distance between the manufacturer and the customer, as well as fuel costs and transportation methods, significantly affect the overall cost. Shipping costs can be substantial, particularly for large orders.

Applications and Use Cases: Metal Barricades For Sale

Source: greenstuffworld.com

Metal barricades, while seemingly simple, are incredibly versatile and find applications across a wide range of sectors. Their primary function is to create temporary barriers, ensuring safety and controlling the movement of people and vehicles. This adaptability makes them essential for many industries and event types.

Metal barricades offer a robust and reliable solution for managing pedestrian and vehicular traffic, providing a clear visual demarcation of restricted areas. Their strength and durability ensure they can withstand significant impact, making them suitable for various challenging environments.

Construction Site Applications

Metal barricades are indispensable on construction sites, acting as safety barriers to protect workers and the public from hazardous areas. They delineate work zones, separate pedestrian walkways from active construction areas, and prevent unauthorized access to dangerous equipment or materials. Proper placement is crucial for minimizing risks associated with heavy machinery, falling debris, and uneven terrain. For example, barricades can effectively cordon off excavation sites, preventing accidental falls or equipment damage.

Event Management and Crowd Control

Large-scale events, from concerts and festivals to sporting events and political rallies, heavily rely on metal barricades for crowd control and safety. They channel pedestrian flow, create designated walkways and waiting areas, and prevent overcrowding in vulnerable zones. The ability to quickly assemble and dismantle these barricades makes them ideal for temporary event setups. Imagine a large music festival: strategically placed barricades guide attendees to entrances, stages, and restrooms, ensuring a safe and organized experience.

Security and Access Control

Metal barricades are frequently employed for security purposes, limiting access to restricted areas or controlling entry points. They can be used to protect sensitive infrastructure, secure perimeters during emergencies, or manage access to specific locations within a building or facility. In high-security environments, they might be combined with other security measures, such as security personnel, to create a layered approach to protection. Consider a government building: metal barricades could be deployed to control access during a security alert, creating a physical barrier and preventing unauthorized entry.

Safety Considerations

Proper use of metal barricades is paramount for maximizing their effectiveness and minimizing potential risks. Several safety considerations must be addressed depending on the application environment.

It is crucial to select barricades appropriate for the intended application and anticipated loads. For example, heavier-duty barricades might be necessary for areas with heavy vehicular traffic, while lighter-weight options might suffice for pedestrian crowd control. Regular inspections for damage or deterioration are vital to ensure structural integrity and prevent accidents. Improperly maintained barricades can pose a significant hazard.

Furthermore, proper placement and securing of barricades are essential. They should be positioned to effectively block access to hazardous areas or manage pedestrian flow, and they should be firmly anchored or weighted to prevent them from being easily moved or knocked over. Clear signage should be used in conjunction with barricades to provide clear instructions and warnings to those approaching restricted areas.

Finally, the surrounding environment must be considered. In areas with extreme weather conditions, additional measures might be necessary to ensure barricade stability. For example, in high-wind areas, extra weighting or anchoring may be required to prevent the barricades from being blown over.

Scenario: Large Public Event

Let’s envision a large outdoor music festival expected to attract 50,000 attendees. Effective use of metal barricades is critical for safety and a smooth event flow. The perimeter of the festival grounds would be secured with heavy-duty barricades to control entry and exit points. Internal barricades would create separate zones for various activities: stage viewing areas with different levels of access, food vendor areas, first-aid stations, and designated pathways for efficient crowd movement. These barricades would be strategically placed to prevent bottlenecks and ensure safe passage for attendees. Furthermore, clear signage would be prominently displayed on or near the barricades to guide attendees to specific areas and inform them of any safety regulations. Adequate lighting would also be implemented to ensure visibility of the barricades, particularly during nighttime hours. Trained personnel would be strategically positioned to manage crowd flow and address any potential issues. This comprehensive approach, utilizing metal barricades effectively, would contribute significantly to the overall safety and enjoyment of the event.

Maintenance and Durability

Source: imimg.com

Metal barricades, while robust, require proper care to maximize their lifespan and maintain their effectiveness. Regular maintenance not only extends their useful life but also ensures worker safety and prevents costly repairs down the line. Neglecting maintenance can lead to premature deterioration, compromising the barricade’s structural integrity and potentially causing accidents.

Proper maintenance involves a combination of cleaning, repair, and appropriate storage. Ignoring these aspects can significantly shorten the operational life of your barricades, impacting your return on investment.

Cleaning Procedures for Metal Barricades

Regular cleaning is crucial for removing dirt, grime, and corrosive substances that can accelerate deterioration. For steel barricades, a simple wash with soap and water, followed by a thorough rinsing, is often sufficient. For more stubborn stains or rust spots, a wire brush or mild abrasive cleaner may be necessary. Aluminum barricades generally require less intensive cleaning, but regular washing is still recommended to prevent the buildup of dirt and debris. After cleaning, allow the barricades to dry completely before storing them to prevent rust or corrosion.

Repairing Damaged Metal Barricades

Minor dents and scratches can usually be repaired with a filler and paint, matching the original color as closely as possible. More significant damage, such as bent or broken components, may require professional repair or replacement. Regular inspections are vital for identifying and addressing minor damage before it escalates into a more serious problem. Prompt repairs prevent further deterioration and ensure the continued structural integrity of the barricade.

Storage Recommendations for Metal Barricades

Proper storage protects barricades from the elements and extends their lifespan. When not in use, store barricades in a dry, covered area, away from direct sunlight and moisture. Stacking barricades should be done carefully to avoid damage. Using protective covers or wraps can further minimize the risk of corrosion and damage during storage.

Durability Comparison of Metal Barricade Materials

The durability of metal barricades varies depending on the material used. Steel and aluminum are the most common materials, each with its advantages and disadvantages.

| Material | Strength | Weight | Corrosion Resistance |

|---|---|---|---|

| Steel | High | High | Moderate (requires regular maintenance, especially in humid environments) |

| Aluminum | Moderate | Low | High (naturally corrosion-resistant) |

Lifespan of Metal Barricades Under Varying Conditions

The lifespan of a metal barricade is significantly influenced by its usage conditions and the level of maintenance provided. A steel barricade used outdoors in a harsh, coastal environment with minimal maintenance might last only 5-7 years before requiring significant repairs or replacement. In contrast, an aluminum barricade used indoors and regularly maintained could last for 15-20 years or even longer. Regular inspections, prompt repairs, and appropriate storage are key factors in extending the lifespan of any metal barricade, regardless of the material used. For example, a construction site barricade subjected to daily heavy use and exposure to the elements would naturally have a shorter lifespan than a barricade used for crowd control at a temporary event and stored properly between uses.

Suppliers and Retailers

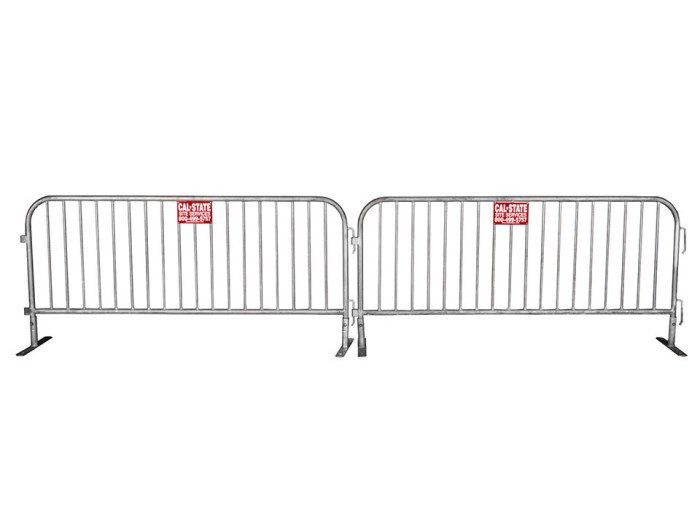

Source: rentfenceandtoilets.com

Finding the right supplier or retailer for your metal barricade needs depends on several factors, including your location, the quantity you need, and your budget. Large-scale projects will have different sourcing requirements than smaller, individual purchases. This section will highlight some key players and the typical sales processes involved.

Choosing a supplier involves more than just price. Consider factors like delivery times, product quality, and the level of customer support offered. A reliable supplier will ensure your barricades arrive on time and meet your specifications, minimizing disruption to your project.

Key Suppliers and Retailers of Metal Barricades

The market for metal barricades includes a range of suppliers, from large manufacturers to smaller distributors. Their geographical reach and product offerings vary significantly. The following list provides examples, but it is not exhaustive.

- National Barrier Corporation (NBC): A major US-based manufacturer with a wide range of barricade types, including temporary and permanent solutions. They offer nationwide distribution and often work with large-scale event organizers and construction companies. Their product line includes standard steel barricades, crowd control barriers, and more specialized options.

- Allied Barrier: Another significant US supplier, offering similar product lines to NBC, with a strong focus on customization and large-order fulfillment. They have a robust online presence and offer detailed product specifications.

- Local Distributors: Many smaller companies specialize in regional distribution of metal barricades. These businesses often offer personalized service and quicker delivery times within their service areas. Finding these requires local online searches or contacting construction supply companies in your area.

- Online Marketplaces: Websites like Amazon and eBay often list metal barricades from various sellers. While convenient, it’s crucial to verify the seller’s reputation and product quality before purchasing from these platforms. Check reviews and seller ratings carefully.

Customer Service and Support Comparison

Customer service varies greatly across suppliers. Larger manufacturers may have dedicated customer service departments, offering phone, email, and online chat support. Smaller distributors might offer more personalized service, with direct contact with the owner or sales representative. Response times, technical expertise, and the willingness to address issues are key factors to consider.

For instance, NBC and Allied Barrier, being larger companies, generally offer comprehensive support systems, including detailed manuals, online troubleshooting resources, and readily available customer service representatives. Smaller, local distributors might provide a more hands-on approach, potentially offering on-site assistance or consultations. However, their support systems might not be as formalized.

Typical Sales Process for Metal Barricades

The purchasing process varies depending on the supplier and the order size. For smaller orders from local distributors, the process may be simple, involving a phone call or in-person visit to place the order. Larger orders from manufacturers often involve a more formal process, including detailed quotes, contracts, and potentially a longer lead time for delivery.

Generally, the process includes: initial inquiry (often via phone or email), quotation/pricing discussion, order placement (often involving purchase orders and formal agreements), delivery scheduling, and finally, payment and receipt of goods. Online marketplaces often simplify the process, with direct online ordering and payment processing, but the buyer assumes more responsibility for verifying product quality and delivery details.

Safety Features and Regulations

Source: building equipment.eu

Metal barricades, while seemingly simple, incorporate several safety features and are subject to various regulations to ensure safe and effective use. Understanding these aspects is crucial for both suppliers and users to minimize risks and comply with industry standards. Properly designed and implemented barricades are essential for controlling pedestrian and vehicular traffic, protecting workers, and preventing accidents.

Modern metal barricades often feature several key safety elements. Sturdy construction, using high-strength steel or other durable materials, is paramount to withstand impacts and maintain stability. Reflective tape or paint is commonly applied to increase visibility, particularly in low-light conditions, helping to prevent collisions. Some barricades also incorporate features like interlocking mechanisms to create continuous barriers, preventing gaps that could compromise safety. The design often prioritizes a stable base to prevent tipping, even under stress. Consideration is given to sharp edges and potential pinch points, often mitigated through rounded corners or protective coverings.

Relevant Safety Regulations and Standards

Various organizations and governing bodies establish safety regulations and standards for the use and installation of metal barricades. These standards often address material specifications, construction requirements, and testing procedures to ensure the barricades meet specific safety criteria. For example, Occupational Safety and Health Administration (OSHA) guidelines in the United States provide comprehensive regulations regarding workplace safety, including the proper use and placement of barricades in construction sites and other industrial settings. Similar regulatory bodies exist in other countries, each with its specific standards and requirements. Compliance with these regulations is crucial to avoid penalties and, more importantly, to ensure the safety of workers and the public. These standards often specify requirements for visibility, stability, and resistance to impact.

Potential Hazards of Improper Installation or Maintenance

Improperly installed or maintained metal barricades pose several significant hazards. A poorly secured barricade could easily topple, causing injury to pedestrians or damage to vehicles. Insufficient visibility, due to lack of reflective materials or poor placement, increases the risk of collisions. Corrosion or damage to the barricade structure can compromise its integrity, rendering it ineffective and potentially dangerous. Furthermore, gaps between barricades, caused by improper installation or damage, create pathways for unauthorized entry into restricted areas, jeopardizing worker safety or security. In extreme cases, a failed barricade could lead to serious accidents, including injuries or fatalities. Regular inspection and maintenance are vital to prevent these hazards.

Illustrative Examples

Source: electriduct.com

Let’s look at some real-world examples of metal barricades in different settings to illustrate their versatility and specific design considerations. These examples highlight how material choices, dimensions, and safety features are tailored to the intended use.

Construction Site Barricade

A typical metal barricade for a construction site is usually a sturdy, heavy-duty unit designed for both safety and durability. Imagine a barricade approximately 4 feet tall and 4 feet wide, constructed from galvanized steel tubing with a diameter of 1.5 inches. The frame is reinforced at key stress points to withstand impacts from vehicles or equipment. The infill might consist of a strong, welded wire mesh panel for visibility while preventing unauthorized access. Safety features include bright, highly visible reflective strips or paint along the top and sides for low-light conditions, and potentially, a base plate for added stability on uneven ground. The overall design prioritizes strength and resilience to protect workers and prevent accidents.

Concert Crowd Control Barricade

For crowd control at a large concert, portability and visibility are key. Picture a lighter-weight barricade, perhaps 3 feet tall and 4 feet wide, constructed from aluminum or powder-coated steel. The lighter material allows for easier setup and breakdown by event staff. The design might incorporate quick-connect features for faster assembly and disassembly. Visibility is paramount, so these barricades often feature bright colors, perhaps bold black and yellow stripes, and may include reflective elements for enhanced visibility in dimly lit areas. Durability is still important, so the design incorporates strong joints and reinforced corners to withstand the pressure of crowds. While not as robust as a construction barricade, it is designed to withstand the stresses of a large gathering.

High-Profile Event Security Barricade

Security barricades for high-profile events demand a high level of robustness and security features. Consider a barricade standing 6 feet tall and 4 feet wide, crafted from thick, heavy-gauge steel. The design might include a solid, unclimbable panel, perhaps made of perforated sheet metal for ventilation while preventing access. The frame would be exceptionally strong, possibly reinforced with additional bracing, to resist attempts at breaching or damaging the barricade. Security features could include integrated locking mechanisms to link multiple units together, making a continuous and impenetrable barrier. These barricades might also incorporate mounting points for additional security measures, such as CCTV cameras or temporary lighting. The overall design emphasizes strength, security, and resistance to forceful entry.

Last Word

Source: com.sg

Choosing the right metal barricade involves careful consideration of several factors, including intended use, budget, and safety regulations. This guide has provided a comprehensive overview of the market, highlighting the diverse types of barricades available, their applications, and the key considerations for purchase and maintenance. By understanding these elements, you can confidently select and implement metal barricades that effectively meet your needs while prioritizing safety and efficiency. Remember to always prioritize safety and comply with all relevant regulations.